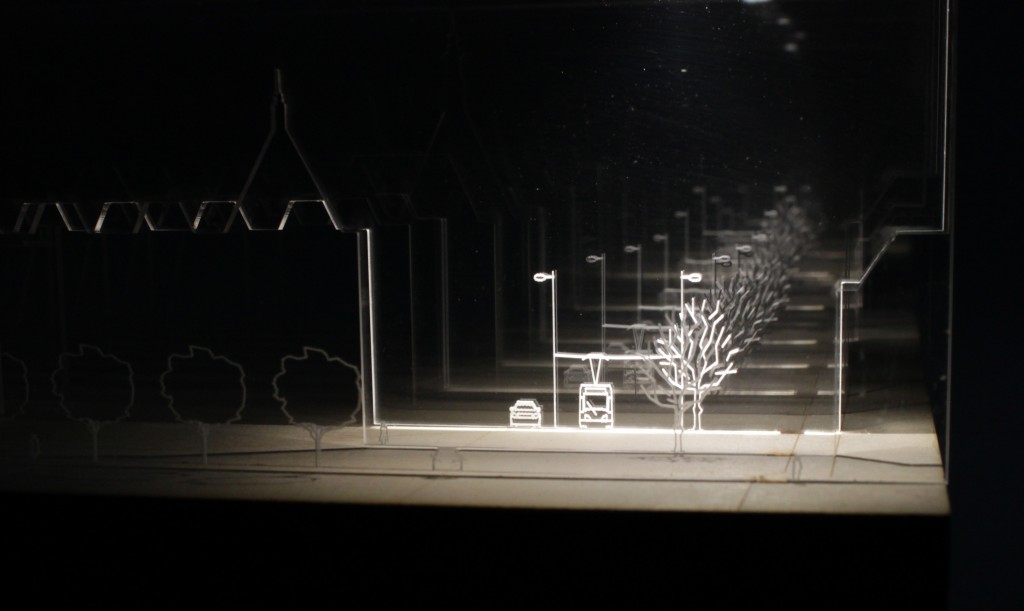

The photo above is a collage of photo’s of a model for the course Analytical Models. The model is made by Daan Zandbergen, David van Weeghel, Jochem Hols and Mart Bremmer and is part of a small exhibition they made about the Stedelijk Museum in Amsterdam. The photo above shows the relation of the old entrance and the city. The model has been constructed using plywood and perspex to create standing transparent ‘slides’. By using light from the side, the lasercutted and engraved lines appear in a dramatic way. This has been repeated for every slide and the photo collage is showing all the layers at once.

Category Archives: Machines

The ‘light’ version

Posted in Appearance, Machines

Tagged Analytical Models, daan zandbergen, David van Weeghel, geert coumans, jochen hols, light, mart bremmer

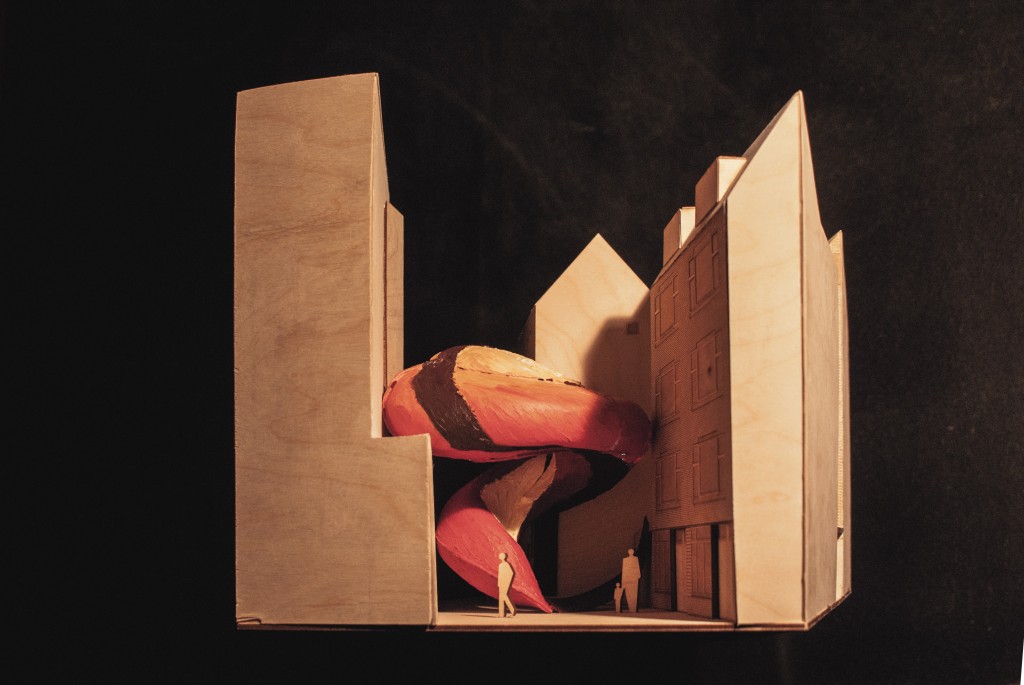

The City as Canvas, Architecture as Painting

The following text is how Tiwánee van der Horst describes her graduation project in relation to the modelling techniques she used to accommodate a time lapse movie.

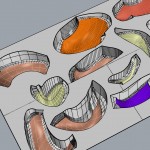

The design for my graduation project was an organic structure where the shape was a result of a three dimensional translation of painterly movements and textures within a narrow alley. With my final model the aim was to show the designed building process through a time-lapse (see movie). For this it was needed to make a transparent surface onto which I could paint, so in the movie it would look like it was extruded in mid air.

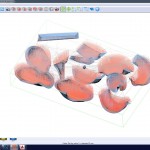

The options were either to 3D print the complex shape with a transparent filament or to deep draw with transparent Vivak. However the filament would never be entirely transparent. Therefore I decided to use transparent Vivak for deep drawing. For this it was necessary to make a mold through CNC milling. I divided the design into separate parts, which could then be laid out horizontally for deep drawing, after which all the parts could be glued together, creating the transparent paint surface.

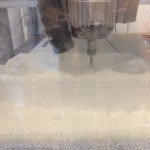

The rhino file was prepared for the CNC milling process by the CAMlab. Because the deep drawing shows every single inaccuracy of the mold we let the CNC milling machine run multiple times until a smooth surface could be made out of the material. To prepare the mold for the deep drawing process it is necessary to create air holes through the block from the deepest points in the mold. To find these points I used a little ball from a bicycle wheel. After having found all the deepest points, the next step was to drill the holes through the block. The holes needed to be as small as possible other wise the holes would show in the surface of the Vivak. As the block was about 11 cm high it was not possible to drill through the block with the 1,5 mm drill. From the back I used a drill with a larger radius. However this process resulted to be to tedious and to risky. We needed to find another way.

With the help of the staff of the modeling hall we found a bicycle spoke with which we could drill small holes through the entire block height.

With all the air holes drilled and the corners smoothened it was time to give the deep drawing a try, but the block was too high and too large.

To reduce the height by 14 mm we used a thicknessing machine and attached the block to a board with double-sided tape to insure the block to stay in place. Finally we succeeded to fully deep draw the block. Next up was the removal of the Vivak from the mold, by blowing air through the holes from the back.

I removed the surfaces that I needed for the model using a saw and utility knife. After attaching all the pieces together it was time to start the painting process. I set up the camera and lighting, prepared the color palette and started painting. The result of which is shown in the movie, giving a first impression of what a building process might look like when architecture becomes as painting.

TRA-DIGITAL HYBRIDS

The following text is how Nadia Remmerswaal describes the project.

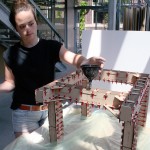

During my graduation project I have focused on designing a safe housing solution for the Kampung of Indonesia. Making up 80% of the Indonesian cities, the Kampung are housing areas that are famous for their informal, self-build, organic growth that houses the low-to mid-low income city dwellers. It is paramount for these mega-cities like Bandung to be densified, but research shows that insufficient building knowledge is available in these Kampungs to construct higher than two storey buildings.

In my research I have focused on using new technology, like CNC milling, to design a durable, affordable, customizable and above all safe building system that enables the local community in these informal areas to build up to four storeys high.

Nadia designed a re-useable moulding technique. To test and show the quality and esthetics she build a 1:7 scale mould and concrete scale model. In the building process laser cutting would be replaced by CNC-milling. The photo’s above show the process of the model: taping the MDF laser cut, building the mould, pouring concrete, covering the mould and the end result.

The tile wedges made it possible to simulate wooden wedges on a smaller scale. A bonus is the impression of the seams in the mould visible in the surface of the concrete. Nadia has been nominated for the archiprix and she is competing for the ASN world prize.