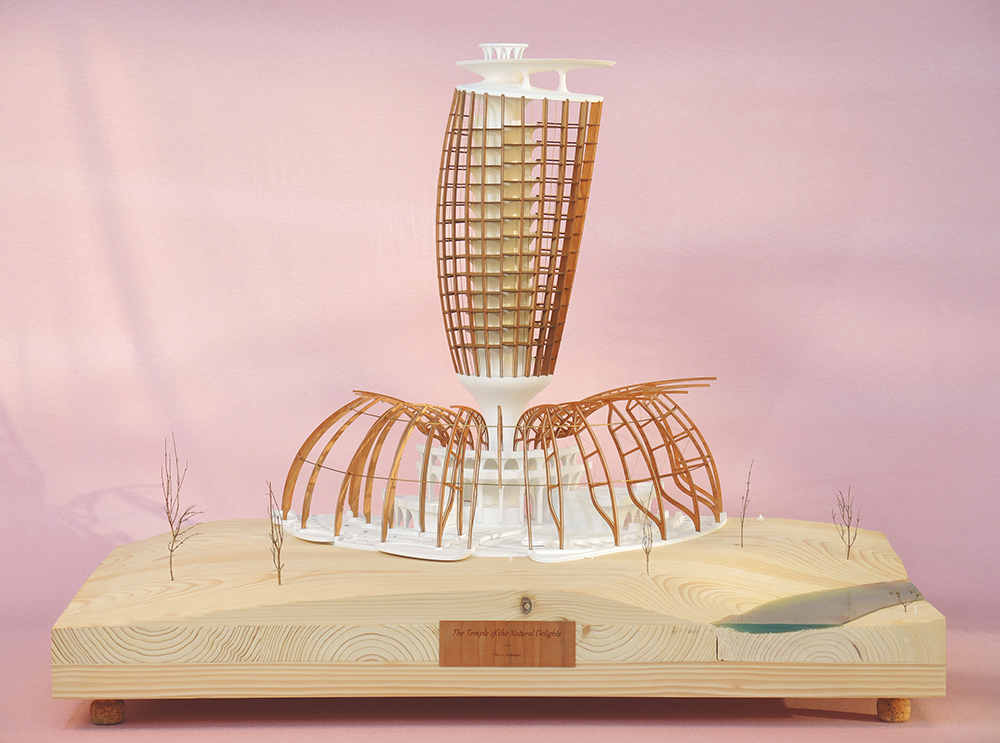

The aim of the project is to accelerate the transition towards a longer lasting society. A new narrative is advocated to engender the desire for a sustainable future. Within this new narrative, temples are situated in the great metropolises of the world to propagate ecological thinking. The aesthetic and architectonic expressions throughout the public and private realms embody an ethic that endeavours to seduce one to live this new lifestyle. The building and its context are an autarkic unity; designed to satisfy the user’s needs through the use of natural principles in synergy with the ecosystem. Building physics, construction and material considerations form the basis of the generic design. The building materials are recycled and absorb greenhouse gases, thus counteract climate change. Its archetype is to be adjusted depending on the geo-specific context and climate of the proposed temple, creating a network of true localised altars to the Natural Delights.

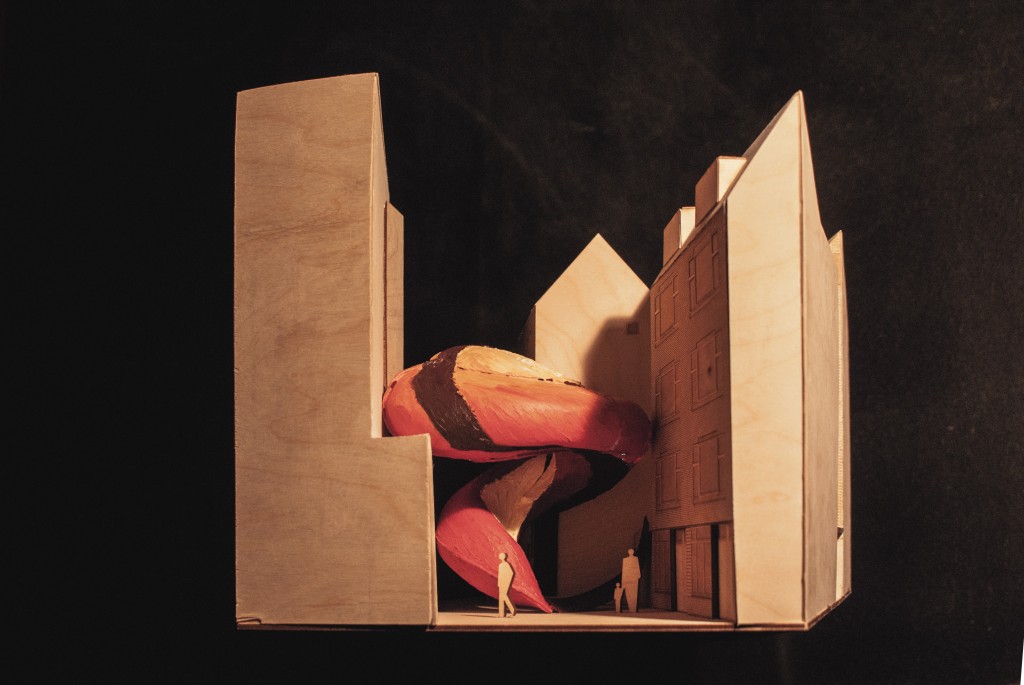

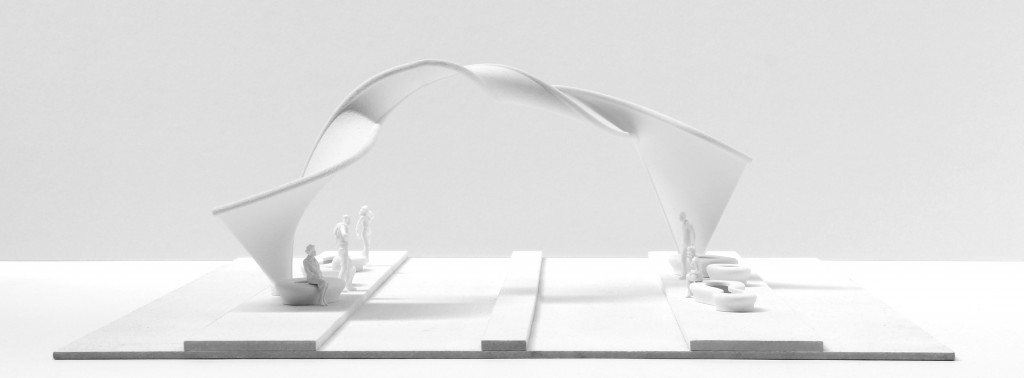

Due to the holistic approach to the design of the building it was important to show the complete building in a 1:200 scale model. One of the results aimed for with this project is to provoke in order to create discussion; how should architecture behave in times of ecological crisis? Thereby it will hopefully contribute to the architectural discourse. With this goal the model could contribute by seducing its viewers, therefor a certain level of expressive aesthetics needed to be achieved. At last the model functioned as constructional test. The gypsum 3d printed elements in the model compare with the 3d printed ‘Ferrock’ elements in the design. Even so the lattice beam construction functions with an actual pressure ring in the model. No glue is used and therefor resembles how it will work in reality.

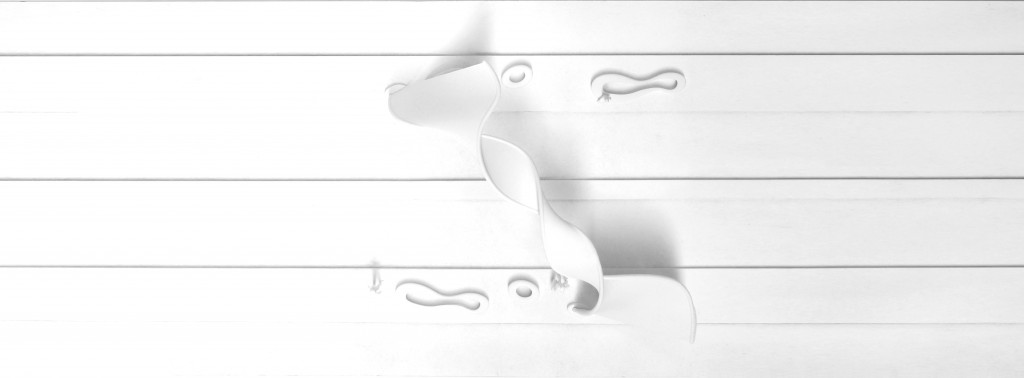

A big question in the whole process was how to make the model of such an extraordinary design. The double curved geometry with these small sizes where only able to construct by 3d printing. I chose for the gypsum printer, because it is so refined and thereby has a beautiful appearance. Also it prints faster than the plastic printer. On the other hand it is expensive, fragile and time consuming to dig out the prints. The printer lays layers of powder and with a laser solidifies the volumes. When the machine is finished there is a block of powder with the solid piece inside. One really has to dig the print out and clean it as an archaeologist. After it’s cleaned a hardening spray can finish the printed elements in order to gain strength. A couple of layers can be applied, not too much, in order to keep the pleasing texture of the gypsum.

The base of the model was CNC milled out of a block of cross laminated pine wood, subsequently sanded and adjusted by hand in order for the 3d prints to fit. A total of six prints where needed to build the model, because of the limiting size of the printer. Gypsum can’t bear bending forces; therefor I introduced small wooden sticks inside the model to maintain stability. All the printed elements where modelled in rhino. The 3d printing program needs to have digital 3d models with closed edges; otherwise it is not able to print. With these organic shapes it can be hard to ban all ‘naked edges’. The wooden structure around the 3d printed part of the model cut by lasers. Due to the fact that it is such a small structure I chose to layer the beams with a Perspex frame on the inside; to gain strength and two layers of veneer on the outside; to maintain a certain aesthetic. For the tension cables is chosen for brass threat which is wired in-between the layers. It is inherent to every scale model to be an abstract representation of reality. Different levels of abstraction could be used depending on the specific story one wants to advocate through the architectural model. During the process it became clear that this model required a certain level of abstraction. Although the model is incomplete it contains an aesthetic value through its purity and functions as an expression of construction.