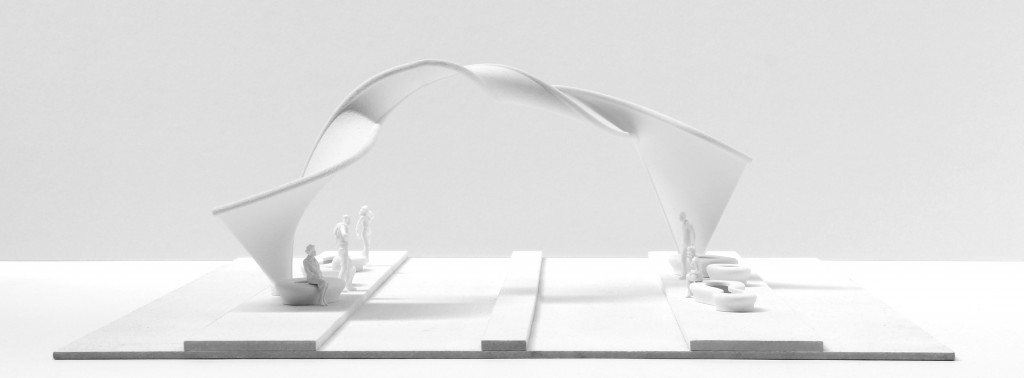

These photos show the process and the end result of the Allegonda project, a cooperation between Modelling Techniques and museum De lakenhal. The model is part of the new exhibition at the museum, soon to be reopened in Leiden. It shows the situation in 1917, reconstructed according to the design by J.P. Oud. The core of the model has been constructed in perspex, cladded by white cardboard. For the most complicated parts we used inserts, 3d printed in gypsum.

Tag Archives: geert coumans

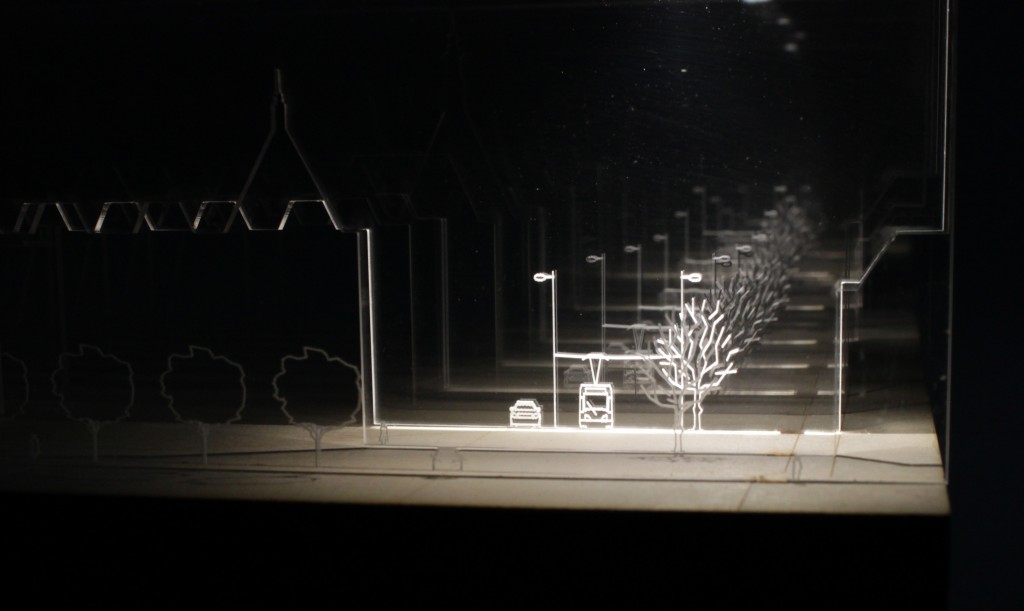

The ‘light’ version

The photo above is a collage of photo’s of a model for the course Analytical Models. The model is made by Daan Zandbergen, David van Weeghel, Jochem Hols and Mart Bremmer and is part of a small exhibition they made about the Stedelijk Museum in Amsterdam. The photo above shows the relation of the old entrance and the city. The model has been constructed using plywood and perspex to create standing transparent ‘slides’. By using light from the side, the lasercutted and engraved lines appear in a dramatic way. This has been repeated for every slide and the photo collage is showing all the layers at once.

Posted in Appearance, Machines

Tagged Analytical Models, daan zandbergen, David van Weeghel, geert coumans, jochen hols, light, mart bremmer

TRA-DIGITAL HYBRIDS

The following text is how Nadia Remmerswaal describes the project.

During my graduation project I have focused on designing a safe housing solution for the Kampung of Indonesia. Making up 80% of the Indonesian cities, the Kampung are housing areas that are famous for their informal, self-build, organic growth that houses the low-to mid-low income city dwellers. It is paramount for these mega-cities like Bandung to be densified, but research shows that insufficient building knowledge is available in these Kampungs to construct higher than two storey buildings.

In my research I have focused on using new technology, like CNC milling, to design a durable, affordable, customizable and above all safe building system that enables the local community in these informal areas to build up to four storeys high.

Nadia designed a re-useable moulding technique. To test and show the quality and esthetics she build a 1:7 scale mould and concrete scale model. In the building process laser cutting would be replaced by CNC-milling. The photo’s above show the process of the model: taping the MDF laser cut, building the mould, pouring concrete, covering the mould and the end result.

The tile wedges made it possible to simulate wooden wedges on a smaller scale. A bonus is the impression of the seams in the mould visible in the surface of the concrete. Nadia has been nominated for the archiprix and she is competing for the ASN world prize.

Toolbox

David Svahn, Hans Ahrland, Roman Oost and Roel Kosters each made a series of models for the Analytical Model course. The subject for this group was the NMM (Nationaal Militair Museum) in Soesterberg. This model is called ‘The Toolbox’ and can be seen as an assembly of building parts put together with the same proportions as in the original building. By remaking the models the message of the analysis comes across really clearly in the end. After every stage the group of students can discuss and refocus the analysis.

Kunsthal

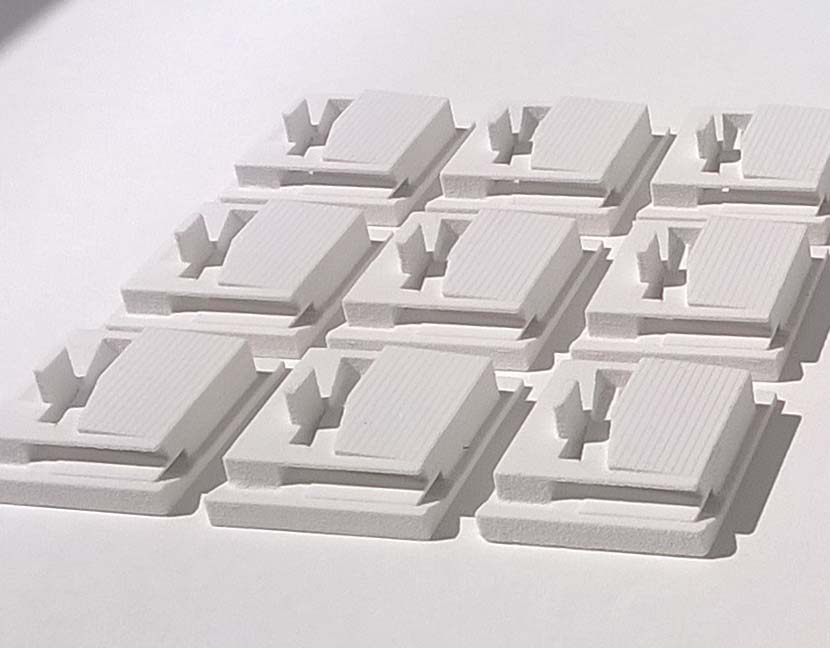

Kunsthal OMA 1:2000, 3d prints in gypsum. The results of the workshop about the project are being exhibited now at the faculty.

Bus stop model

Concrete wall

Nice example of a graduation project, visualized in actual concrete in combination with wood and steel mesh. Mould is constructed with lasercutted mdf, finished of with vivak. The doors are pieces of foam to enable demoulding.