The following text has been written by Max Nibbrig to explain his graduation project. Please click on the photos and take a good look. Max learned about the craft of bronze casting, but already knew about photography. And that’s an understatement.

Foundry pt.1

For my graduation project I designed a bronze foundry for the city of Amsterdam. The project aims at bringing back craft in to the city again by introducing a new place of work. Foundry pt.1 uses photography as a tool to explain architectural design. The images are pictures of 1:20 architectural scale models. These pictures explore spatial quality in relationship to light, atmosphere, material and use. The photo series consist out of 11 pictures divided in to four themes; Foundry, Foundry Ceiling, Artist in Residence and Material and Detail. Moments within these four themes are carefully framed to show the potential of the space and the design.

The design consists out of two buildings. The big hall is a foundry for the casting of bronze and brass. On the central axis of the building the furnace is located where metals are melted. To the left and right there are casting pits where moulds can be placed to cast metal. Along the vertical axis of the building all the technical necessities as lighting, ventilation and movement are arranged.

The smaller space is an artist in residence building where artist can work in close cooperation with the foundry. He has his atelier on the ground floor and his living space on the first floor, making it possible to look down on the work whilst not working.

Both spaces deal with a floor that changes in to a plinth when the floor meets the wall. The plinth and floor work together to define a work area where things can be created.

Foundry pt.2

For my graduation project I designed a bronze foundry therefore I wanted to explore the possibilities of metal casting myself. Here fore I participated in a metal casting workshop organized by the Crafts Council in the Netherlands. In this workshop I had the possibility to create a metal casted site model of the location of my graduation.

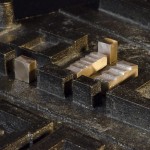

I researched the possibilities of combining an old craft together with new production techniques. Sand casting is an old production technique for the casting of metals. This technique uses sand mixed with oil to create a mold. But before the casting can start the model needs to be created first. I made the site model first by 3d printing all the surroundings buildings and gluing them to a CNC-milled base plate. This model was then used to create the mold where the brass was casted in to.

In the accompanying pictures and movie you can see the process starting with the 3d printed objects to the finished model. The site model is in a 1:1000 scale and made out of solid brass. The four shinny bronze blocks is the final design of my graduation project. The ‘’legs’’ underneath the model are the air outlets of the mold. I decided to leave these on the model as a reference to the casting process.

Movies:

-Crafts Council video:

https://vimeo.com/132807849

-Sand casting a 1:000 architectural scale model in solid brass:

https://youtu.be/SIZ96zbk2D0